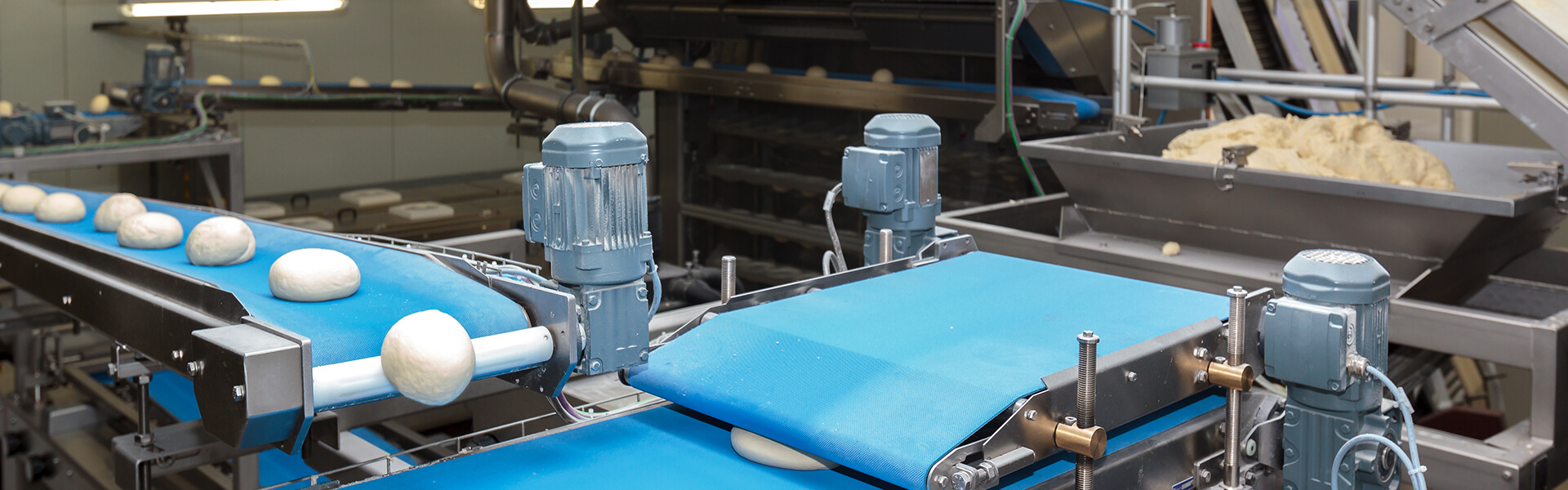

Welcome to part 3 of our humidity in food production series, where we look at all the areas of food production that rely heavily on humidity control. If you haven’t read the first few already, you can read part 1 here (crops and harvesting), and part 2 here (meat production). But today, we wanted to look into a slightly different area of food production – one that requires a bit more human intervention. Baking and bread production.

Humidity and Baked Goods

In our previous articles, we’ve talked about how humidity control allows produce to be kept fresh and cool, improving quality for the consumer and profit margins for the producer. But in the baking industry, humidity control plays a slightly different role.

When you consider the types of breads found around the world, you will notice that their regional climate has a pretty big influence over their characteristics when baked. For example, crusty breads tend to come from arid dry, barren areas, while soft breads will come from more humid regions. And even if a bakery can import the best ingredients for around the world, they can’t import a climate to go with them. So if they want those characteristics in their bread, they need to be able to replicate those conditions in their bakery. That’s the primary purpose of humidity control in the bread baking world, and it impacts the production of bread in 3 ways: storage, dough proofing, and baking.

Bread Storage

The need for a controlled environment in a bakery actually starts before you bake a single thing. Many of the ingredients required for baking bread perform their best and maintain their quality when relative humidity levels are lower and temperatures are cooler. For example, yeast is extremely perishable when exposed to moisture and heat, so it needs to be kept in a cool, dry environment until it’s ready to be used. Other ingredients will start to oxidise as the relative humidity gets lower, which means they will absorb more water and begin to grow mould. Most baking ingredients will also last longer at cooler temperatures and lower humidity, so keeping them in a controlled environment will vastly improve their shelf life.

The need for a controlled environment in a bakery actually starts before you bake a single thing. Many of the ingredients required for baking bread perform their best and maintain their quality when relative humidity levels are lower and temperatures are cooler. For example, yeast is extremely perishable when exposed to moisture and heat, so it needs to be kept in a cool, dry environment until it’s ready to be used. Other ingredients will start to oxidise as the relative humidity gets lower, which means they will absorb more water and begin to grow mould. Most baking ingredients will also last longer at cooler temperatures and lower humidity, so keeping them in a controlled environment will vastly improve their shelf life.

Storage can also make or break a bake once it’s cooked. Overly humid conditions will soften crisp crusts, make crisp crackers lose their crunch or inhibit the drying of dough (which is essential for good pasta). Baked goods will develop mould rapidly in humid conditions, but if the environment becomes too hot and dry, then you risk drying out goods that need to stay moist, like cakes and rolls. The only way to ensure a bakery environment stays at the correct humidity and temperature for the entire baking process is with a professional humidity control system.

Dough Proofing

A quick rundown – proofing is the process used to take bread-based products from a batter to a risen, air-filled dough. Once the ingredients have been mixed to form a dough, it will be left for a certain period of time to ‘rest’. During this time, the yeast within the dough ferments, creating air pockets and expanding the size of the dough. Without a good rise, breads can become flat, dense and chewy (and if you don’t believe us, just watch bake off!!) But yeast is a living organism, which means it’s very sensitive to its environment. Everything from the water content in the dough, the temperature of the room it’s being proofed in and the relative humidity can have an impact on how the yeast ferments. To ensure this process goes smoothly and produces a consistent result, many bakers will use a proofing cabinet or a dough fermentation room – in which they can exactly control the environment. To ferment properly the average dough requires a relative humidity of at least 75-80%, but it can vary depending on the variety of bread being baked. This means you not only need a tightly controlled environment, but one that you can change the temperature and RH of whenever you need to.

Baking

Then we get to the fun part – the baking! Baking goods involves a lot more than putting some dough in the oven. For example, did you know that the amount of water vapour in an oven affects the baking times, as well as the crust on the finished product? There are even some bread recipes that call for you to add a bath of water to the bottom of the oven to achieve a crispier crust. So the humidity of the air you’re baking in can have a big impact on the quality of your finished goods.

Then we get to the fun part – the baking! Baking goods involves a lot more than putting some dough in the oven. For example, did you know that the amount of water vapour in an oven affects the baking times, as well as the crust on the finished product? There are even some bread recipes that call for you to add a bath of water to the bottom of the oven to achieve a crispier crust. So the humidity of the air you’re baking in can have a big impact on the quality of your finished goods.

Bakerpedia explains that forced convection ovens have relative humidity levels of 30 to 60 percent with lower temperatures. Natural convection ovens have humidity levels of 90 to 95 percent with higher temperatures. When humidity levels are higher, baking times are longer because moisture evaporation and gluten coagulation in the crust slow. Arid conditions can cause goods to over-bake, making them too tough. So really, the best humidity level for a bakery depends on what it’s baking at the time. That means they need to be able to control the conditions of their bakery at all times, regardless of the actual weather conditions outside.

That’s what we do. At Humidity Solutions, we supply humidity control solutions to farms, cold stores, bakeries and more – helping provide the perfect environment for proofing and baking, every time. If you would like to know more, just get in touch with us today.