|

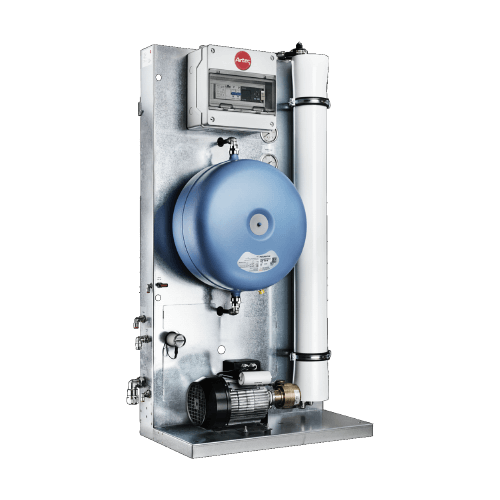

Reverse Osmosis (RO) is a water purification process that uses a partially permeable membrane to separate ions, unwanted minerals and larger particles from mains water. The sequence to produce fully treated water is to pass the mains water through a water softener to remove the hard calcium and to replace it with sodium – this helps to prevent hard scale from blocking the reverse osmosis membranes. Carbon filters would then remove the chlorine from the water – chlorine ‘eats’ the membrane which reduces the membrane lift significantly. RO differs from filtration in that the mechanism of fluid flow is by osmosis across a membrane as opposed to straining through a membrane filter. It is possible to use the RO plants without the softener or carbon filter, depending on the application. Using Reverse Osmosis to remove the minerals from a humidifier’s supply water, virtually eliminates all limescale that would otherwise build up, and results in much lower levels of maintenance required and energy consumption. |

|

Humidifier Technology and Reverse Osmosis

Electrode Boiler

Electrode boiler humidifiers work on technology that passes a current between electrode plates within an internal, industrial strength plastic, steam cylinder to generate its steam.

To enable conductivity within water requires some minerals, (50 – 500ppm for Humidity Solutions’ Vapac units), so they are best to run on a mains water supply and water treatment systems are not ideal with this type of humidifier. Scale will naturally develop over time as the minerals are left behind when the water is boiled into steam. Because of this, the steam generating cylinder will require replacing or cleaning periodically, depending on the water quality and hours run. It is an initially lower capital cost humidifier option but does coming with ongoing consumable costs.

|

Resistive The Resistive steam humidifier on the other hand, uses technology much like in your kettle at home. It has a heating element which physically boils the water within a stainless-steel internal chamber. Because of this, these units are able to run on mains or RO water as there is no electrical current required to pass through the water. If RO is used then this can drastically reduce the maintenance requirements as very limited scaling will occur, and greatly improve the unit’s working lifespan. By using resistive steam humidifiers fed by RO water, ±1%RH control can be achieved. This is because the humidifier does not have to drain and refill with cold water – a process used to manually reduce the mineral build up in the cylinder. This helps the unit maintain the boiling temperature which, in turn, maintains steam output and control. Due to the nature of this technology, it has a higher capital cost but then very few consumable item costs going forwards. This unit is ideal for close control test chambers and laboratories, or on critical sites where production demands consistent output and close control. |

|

Adiabatic/Ultrasonic To complement our isothermal (steam) humidifiers, we also have a wide range of cold water systems using both High Pressure Adiabatic (cold water) and Ultrasonic technologies. Rather than producing steam, these technologies produce a fine spray or misting effect to reach their required humidity levels which drastically reduces their electrical requirements consumption and costs, making them very attractive for many projects. In the case of the spray adiabatic humidifiers, the water is raised to a high pressure and distributed through hoses to nozzle outlets that then disperse the fine atomised spray. The nozzles are robust but mineral dusting can occur as the minerals precipitate out of the atomised water. In most applications this is not an issue, however in digital printing and electronic production reverse osmosis water may be required to prevent this effect which could affect production if not considered. Ultrasonic humidifiers, on the other hand, have internal oscillators that ‘vibrate’ the water into a fine mist that can be dispersed into the space. If these units are run on a mains water supply, once the water molecules have been dispersed then the mineral particles are left behind and create scale which will reduce oscillation and reduce production of mist/moisture. RO water is therefore required with these units. |

|

Hygiene

All our humidifiers are Legionella safe when maintained correctly and all have control safeguards.

With both the Electrode and Resistive technology humidifiers, the boiling process they both create eliminates any risk of bacteria or legionella build up and, if there hasn’t been any demand for a set number of hours, these units will automatically drain so there isn’t any warm standing water which can create this risk. As an extra precaution, our steam lance dispersion systems are angled so if any condensation does occur within them, this water will run back to the humidifiers ready to be used again.

As the boiling process isn’t present within the Adiabatic and Ultrasonic units, there has been a common misconception that these aren’t always safe. However, we provide UV steriliser lights on the water supplies as standard for both of these types of units which, combined with water management, makes them safe to use.

In conclusion, in many humidification systems, Reverse Osmosis water treatment is an effective and economic way of removing unwanted minerals from water. The principal benefits are:

- Eliminates scale build-up in humidifiers

- Reduces maintenance time and cost

- Reduces energy consumption

- Enables precise humidity control

- Extends humidifier life

RO water treatment can be used with a variety of humidifiers and, given the significant benefits and cost savings in terms of reduced energy consumption and lower ongoing maintenance, the payback on original investment can be quick.

Speak to one of our specialists to find out more.